Material CSR Issue

Innovation for the future

Why is it important?

We believe that our most important social responsibilities are to provide new products and services that meet society’s needs, help solve issues facing the world in order to pave the way to a sustainable society, and create economic value. In the market, where technological advancements are rapidly heating up the competition, first movers get the lion’s share. Working against this backdrop, we will think outside the box and push the envelope in our aluminium-based business as we move ahead at full speed to build a brighter future and create value.

Our Approach

The Toyal Group moves ahead with the R&D and commercialization of products by harnessing its core technologies at its Advanced Technologies Division and New Business Creation Department in response to current and potential issues facing society as well as changes in the market environment. We divided target markets into three types, i.e. existing, new, and next-generation markets, and invest R&D in each category. We actively promote open innovation, partnering with startups, universities, research institutions, etc. across the globe, to tackle challenges we cannot overcome alone.

Taking the Creating Shared Value (CSV) approach, we focus on R&D projects that will create value for both society and the Toyal Group while staying in close touch with stakeholders. We will think outside the box and push the envelope of our aluminium-based business to lead the world.

OUR PERFORMANCE

Exploring new possibilities of aluminium applications by Introducing “Aluminium continuous casting facility” (Kanbara Works)

Toyo Aluminium K.K. introduced the continuous aluminium casting facility at its Kanbara Works in October 2018. The continuous casting method not only improves manufacturing efficiency, as compared with conventional methods, but also is expected to, among other things, enhance hardness, reduce pinholes, and reduce molding defects due to improved rolling ratios. Furthermore, in our newly introduced continuous casting facility, detailed settings can be made for manufacturing conditions, enabling us to develop products that can satisfy customers’ needs. We will explore aluminium’s unfound possibilities through development of functional products that can help people live more comfortably

Aluminium continuous casting facility introduced at Kanbara Works

Reducing environmental loads through new technological developments, including water-based paint and metal 3D printers

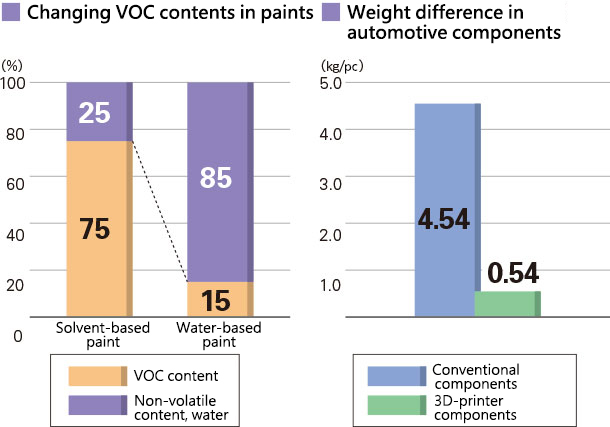

Metallic pigments used for automobile paints were conventionally applicable only to solvent-based paints containing significant VOC* contents. The surface finishing technologies of Toyo Aluminium K.K., however, has made it possible to reduce VOC contents in paints by about 80% by making such pigments compatible with various water-based paints*1.

We also develop and manufacture aluminium-alloy powder for metallic 3D printers for manufacturing automobile components. By using designs optimized for 3D printers and our proprietary high-strength aluminium-alloy powder (Scalmalloy®*2), we have been able to reduce weights of components by more than 80%, which is reported to have contributed to improved mileage of vehicles, the end products*3.

We are determined to enhance partnerships with various industrial fields, expand our technological bases to new areas in close collaboration with stakeholders, so that we can contribute more to reduction of environmental loads.

* VOC: Volatile Organic Compound. Because it causes photochemical smog, it is restricted by regulations in many countries.

*1 Onoyama, Paint Technology; October 2006, Special Number 43 (2006)

*2 Scalmalloy® is a registered trademark of APWORK.

*3 Jon Meyer , Metal additive Manufacturing, Spring 2019 Vol.5 No.1

Full-scale manufacture/sale of products contributing to dissemination of renewable energy

In fiscal 2018, Toyo Aluminium K.K. started the full-scale manufacture/sale of “Hane™ Module” (hereafter, “Panel”), a super-light-weight solar battery panels. The Panel weighs about half of conventional solar battery panels (6 kg/m2), making it possible to be installed on roofs, which used to be impossible due to weights. By taking advantage of the special features of the Panel, we started manufacture/sale of a solar battery panel, “ENESTAND™*4,” a two-pillar solar battery stand that can be installed in a limited space. ENESTAND™ is expected to be used widely at various locations, as a weather protection in an automobile/bicycle parking spot,in front of a guard station, or over a sidewalk, etc. We will make the full use of our proprietary technologies for a society where renewable energy is nothing special in our daily life.

*4 ENESTANDTM,” is a registered trademark of Sky Japan Co., Ltd.

“ENESTAND™,” a small-footprint solar battery stand equipped with “Hane™ Module,” super-light-weight solar battery panel