Brazing pastes: Toyal Hyper Braze®

Aluminium brazing paste

Clearly distinctive from conventional products, it was developed for the NOCOLOK® brazing method and has both the coating performance of ink and the convenience of brazing paste.

No need for fluxing because flux is already contained, and the brazing material composition and the flux compounding ratio can be adjusted to customer requirements.

Features

-

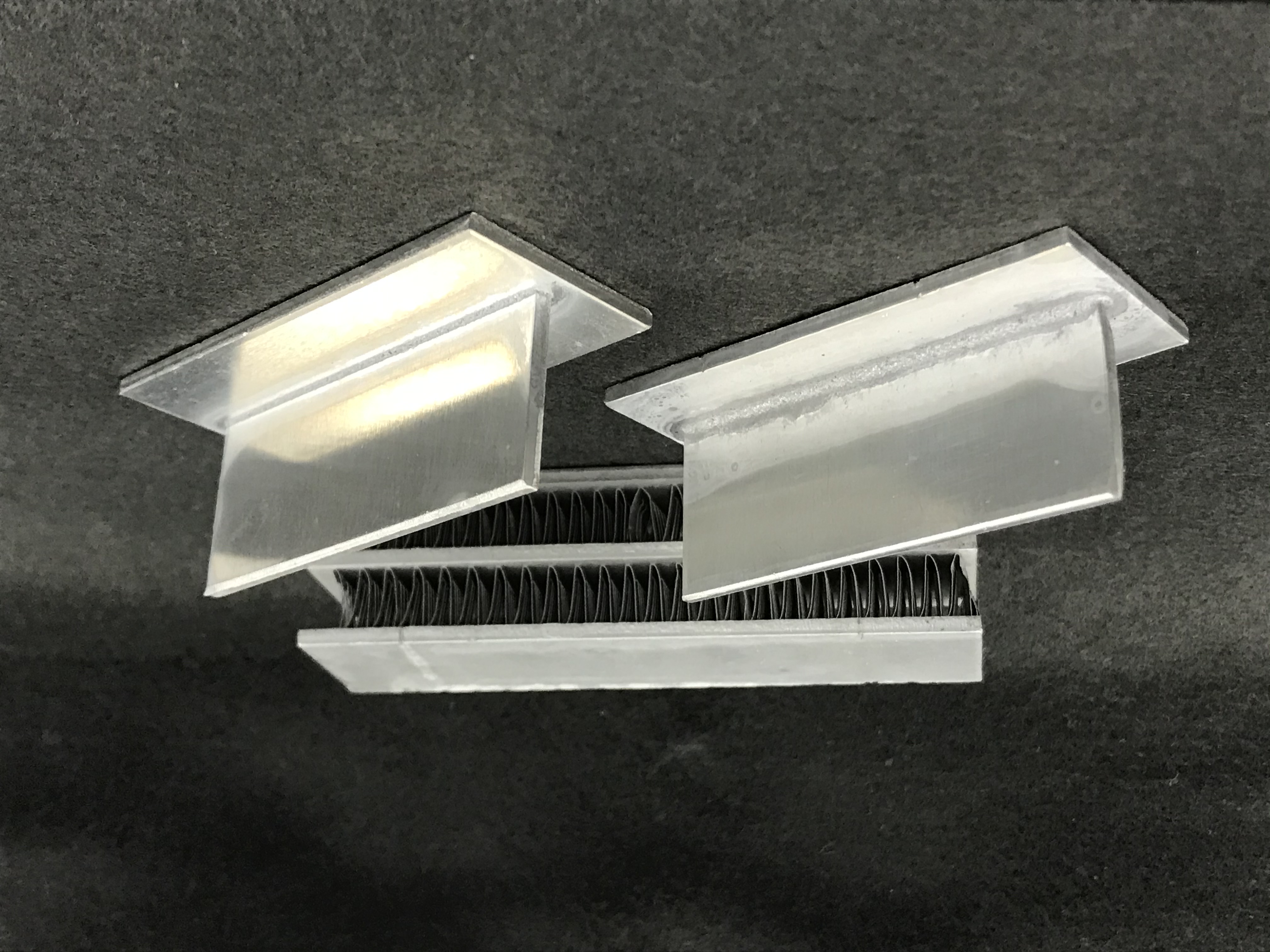

- ・Excellent brazeability, beautiful appearance after brazing

- Video demonstration of brazing (Brazing material: A4045, Joining material: A3003)

-

- ・Excellent coating performance. Coating patterns and the coating amount control are easy.

- Video demonstration of coating using a dispenser

-

- ・Excellent adhesion after coating and drying. Will not peel off and fall during the processing.

- Video demonstration of adhesion after coating and drying

Applications

Automobile heat exchangers made from aluminium, aluminium heat sinks

* "NOCOLOK" is a registered trademark of Solvay Fluor GmbH.

*Our laboratory brazing furnace for aluminium is available for client tests with Toyal Hyper Braze®.

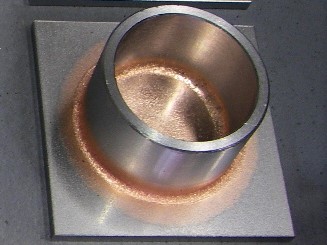

Brazing paste containing copper brazing powder

Pure-Copper brazing paste with excellent brazeability and coating performance.

Applications

Joining of ferrous parts

| Grade | Brazing material | Components | Density | Brazing Methods | Use | |

|---|---|---|---|---|---|---|

| Metal powder | Flux | |||||

| AF524F | A4047 Al-12%Si |

46.4% | 19.8% | 1.5g/cm3 | CAB(Controlled Atmosphere Brazing) Methods | Aluminum Aluminium alloy |

| NT7129S | B-Cu99-1083 ≧99.0%Cu |

86.0% | - | 3.9g/cm3 | Inert gas atmosphere furnace | Carbon steel Stainless steel |