CORE COMPETENCY

Powder plating technologies

We can plate silver, gold, copper onto various organic/inorganic materials.

Features

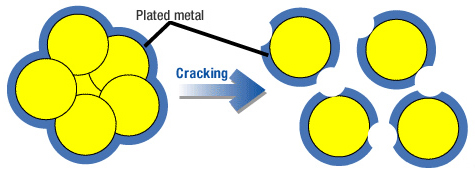

Conventional technologies

With conventional technologies, the particles were plated in an agglomerated state. This meant that after they were broken up, there were many areas on each individual particle that had not been plated and they did not function correctly.

agglomerated stateThe plating is performed on the surface whilst the particles are in an agglomerated state.

crackingThe parts that were touching other particles in the agglomerated state have not been plated.

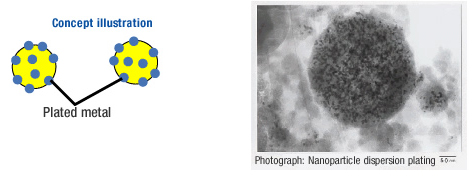

Toyo Aluminium technology No.1

Technology to plate fine particles whilst dispersing them to prevent agglomeration.

<Features>

■Functions are imparted by completely covering the surface with the plating layer.

■There are hardly any unplated areas on the surface of the particles after they are broken up.

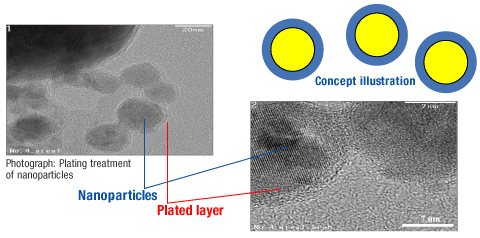

Toyo Aluminium technology No.2

Plating technology to disperse and precipitate metals on the base material surface as nanoparticles.

<Features>

■The surface area increases dramatically and the chemical reactivity is raised.

■A synergistic effect is obtained between the physical properties of the base material particles and the metal particles of the plating.

Toyo Aluminium technology No.3

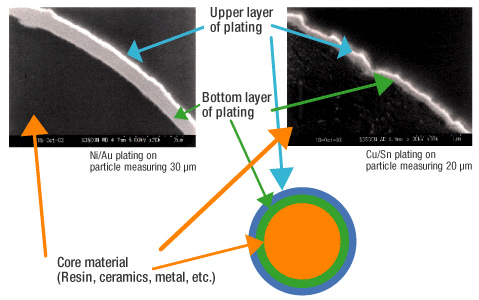

Multi-layer plating is also possible on fine particles measuring just a few microns.